Audit schedule and an audit agenda, what’s the difference?

Internal audit and supplier audit programs both require an audit schedule and an audit agenda, but what’s the difference between them?

What is an audit schedule?

An “audit schedule” is not a formal definition in ISO 19011:2018. However, section 5.1 of that standard states that your audit program should include nine different requirements. Item “d” is “d) schedule (number/duration/frequency) of the audits.” Typically, the audit program manager will maintain an annual audit schedule with a date indicating the date the schedule was last revised. The most common example in lead auditor training is a matrix like the one shown below. The left-hand column will list all of the individual processes that are identified in the company’s process interaction diagram, and the top row of the matrix will indicate the month when each process audit will be conducted. Typically, the expectation is to complete the audit sometime during that month, but some quality auditing procedures specify that the audit may be completed the month before or the month after to accommodate the process owner. The regulations only require that you document and maintain an audit schedule, and the standard is only considered guidance.

I use a slide in lead auditor courses that gives the example of an internal auditing schedule provided above. On the surface, this example seems like a good audit schedule. Twelve auditors perform two audits each year. If each audit requires approximately two days, each auditor spends less than two percent of their work year auditing. Unfortunately, a two-percent allocation of time is insufficient to become or remain proficient at auditing. An improvement to the auditing schedule would be to assign fewer auditors so each auditor gets more experience. There is no perfect number, but assigning a few specialists will improve the chances of becoming and remaining proficient at auditing.

What is an audit agenda?

An “audit agenda” is not a formal definition in ISO 19011:2018 either. In fact, the word “agenda” is not even used in ISO 19011. Instead, section 5.5.5 of ISO 19011 states that “The assignment [of the individual audit] should be made in sufficient time before the scheduled date of the audit, in order to ensure the effective planning of the audit.” The audit plan must also be part of the records [i.e., Clause 5.5.7(b)]. Therefore, “agenda” and “plan” may be used interchangeably. Details of audit planning are provided in 6.3.2 of ISO 19011.

6 Steps to Creating an Audit Schedule

There are six steps to creating an audit schedule:

- What were the results of previous audits?

- Which processes are the most important to audit?

- Who should conduct your internal audit?

- How long should your internal audit be?

- Should you conduct one full quality system audit or several audits?

- Is a remote audit good enough?

We will address each of the six steps below.

How do the results of previous audits impact your audit schedule?

The results of an audit include nonconformities, observations for improvement (OFI), and a conclusion regarding whether the quality system is effective or not. Usually, most processes are effective, and there are no nonconformities or OFIs. Therefore, any processes that had a nonconformity or OFI should be prioritized in the audit schedule and audit planning for the future. For internal and supplier audits, a best practice is for the auditor and the process owner to discuss the corrective actions planned and determine the appropriate timeline or implementation of actions planned. Then the auditor can indicate a timeframe for re-auditing the nonconforming process after corrective actions are implemented. This strategy allows the auditor to be part of the effectiveness check. This approach is appropriate for individual process audits but not for a full-quality system audit.

Which processes are the most important to audit?

The primary element impacting the importance of processes is the risk to product quality associated with the process. Usually, support processes are of lower importance because they do not directly impact product quality. In contrast, core processes directly involved in a device’s design, manufacture, and distribution are critical. Most auditors and audit program managers emphasize design controls and production process controls as important areas to audit. However, the distribution area is often neglected. Other core processes are purchasing, sales, customer service, and servicing. Not every process is equally important when comparing two companies. For example, device manufacturers that only make software as a medical device (SaMD) often have very limited purchasing and incoming inspection activities to audit.

Who should the audit program manager assign to each internal audit?

The example of a revised audit schedule provided above identifies the departments where each of the auditors works with color coding. This is done to ensure that auditors are not assigned to audit processes where they might have a conflict of interest (i.e., they would be auditing their own work). This is the most important aspect of assigning auditors. The second most important aspect is to make sure the auditor has the technical knowledge to audit the process. It is challenging to conduct an audit of manufacturing if you have not spent any time in manufacturing before. If auditors are new and their training is in progress, then the audit program manager may assign the auditor to a process specifically to give them more experience with that type of process. Inexperienced auditors often are assigned less important processes that have not changed recently. However, a better approach to training auditors is to give them a challenge with support. Having the new auditor prepare a detailed sampling plan and list of questions before the audit can prepare them for auditing a more challenging, important process that is likely to have one or more nonconformities. Auditing processes that have nonconformities is also the best way to teach a new auditor how to write the audit findings.

The example of a revised audit schedule provided above identifies the departments where each of the auditors works with color coding. This is done to ensure that auditors are not assigned to audit processes where they might have a conflict of interest (i.e., they would be auditing their own work). This is the most important aspect of assigning auditors. The second most important aspect is to make sure the auditor has the technical knowledge to audit the process. It is challenging to conduct an audit of manufacturing if you have not spent any time in manufacturing before. If auditors are new and their training is in progress, then the audit program manager may assign the auditor to a process specifically to give them more experience with that type of process. Inexperienced auditors often are assigned less important processes that have not changed recently. However, a better approach to training auditors is to give them a challenge with support. Having the new auditor prepare a detailed sampling plan and list of questions before the audit can prepare them for auditing a more challenging, important process that is likely to have one or more nonconformities. Auditing processes that have nonconformities is also the best way to teach a new auditor how to write the audit findings.

What should be the duration of each internal audit in your schedule?

The duration of an audit should be based on the results of previous audits, but other important factors include: 1) the number of personnel involved in the process, 2) the complexity of the process, and 3) the risk to product quality associated with the process. The MDSAP program uses a procedure for audit time determination (i.e., MDSAP AU P0008.007: Audit Time Determination Procedure), and the MDSAP audit approach document (i.e., MDSAP AU P0002.008 Audit Approach) classifies processes as having either a “direct” or “indirect” impact upon product quality based upon the applicable clause of the process (i.e., Clauses 0-6.3 are indirect, and Clauses 6.4-8.5.3 are direct). For example, the production processes and design and development processes both involve a large number of people in most organizations, the processes are complex, and both processes directly impact product quality. Therefore, I typically allocate 3-4 hours to each of those processes during an audit. In comparison, incoming inspection often involves one or two people, and the process often involves only one procedure. Incoming inspection is a “direct” process, but less time (e.g., 1 hour) should be allocated to auditing incoming inspection than the other two processes–unless there was a nonconformity in the incoming inspection process during a recent audit or unless the process was recently changed.

Should you conduct one full quality system audit or several audits?

Both approaches have strengths and weaknesses, but there is not a single best way. If I am using employees to conduct an audit, then I typically restrict the scope of the audit to a single process. Alternatively, when I use a consultant to conduct an audit, I typically conduct a full-quality system audit to minimize travel costs. Another strategy I have recommended is to identify the processes that are most important to audit first (e.g., processes with recent changes and/or nonconformities), and these processes are scheduled for individual process audits during the first half of the audit schedule. Then I schedule a full-quality system audit in the second half of the audit schedule. The strategy ensures that all important processes will be audited twice in one year, but every process will be audited at least once.

Remote audits vs On-site audits

Prior to the Covid-19 pandemic, remote audits were rare in the medical device industry. Many NBs insisted that remote audits were not permitted or effective. The pandemic forced the entire industry to create policies for remote auditing and to use remote auditing whenever possible. Now that the pandemic has ended, many companies continue to conduct remote audits to save money. Even NBs are conducting more remote audits for Stage 1 readiness audits during the ISO 13485 certification process. ISO 19011 has a section in the Appendices outlining the differences between remote and on-site audits. However, there is a minimal advantage to conducting an on-site audit of a process where the auditor is expected to spend all of their time in a conference room during the audit. If the audit is going to be done in a conference room, then why not conduct it remotely? The one exception is when most records are paper-based and unavailable electronically. Alternatively, an on-site audit is generally more effective if the process involves observing inspection activities or assembly operations. Remote audits of inspection activities and assembly operations should be reserved for re-auditing or when a process has been audited on-site in the past, but an on-site audit would still be more effective for those processes.

How many times should a process be audited annually?

Many notified bodies will expect companies to audit all processes at least once during the year. However, it doesn’t expressly state this as a requirement in the regulations, and some companies justify skipping processes that are functioning well and have not changed in the past year. Our team is seeing this more frequently as the number of lead auditors worldwide has become scarce due to the requirements of MDSAP, the MDR/IVDR implementation, and unannounced audits. However, I almost never see the opposite justification (i.e., auditing a process more than once a year). If a process has been changed significantly, or there were nonconformities, then re-auditing the process may be used to verify the effectiveness of corrective actions or to verify that personnel are compliant with the revised process.

How to take advantage of the process approach to auditing

Another improvement that can be made to the revised example of an audit schedule is to use the process approach to auditing. Instead of performing an independent document control and training audit, these two clauses/procedures can be incorporated into every audit. The same is true of maintenance and calibration support processes. Wherever maintenance and calibration are relevant, these clauses should be investigated as part of auditing that area. For example, when the incoming inspection process is audited, it makes sense to look for evidence of calibration for any devices used to perform measurements in that area. When production process controls are being audited, maintenance records of production equipment should also be sampled.

If the concept of process auditing is fully implemented, the following ISO 13485 clauses can easily be audited in the regular course of reviewing other processes:

- 4.2.1), Quality System Documentation;

- 4.2.3), Document Control;

- 4.2.4), Record Control;

- 5.3), Quality Policy;

- 5.4.1), Quality Objectives;

- 6.2.2), Training;

- 6.3), Maintenance;

- 6.4), Work Environment;

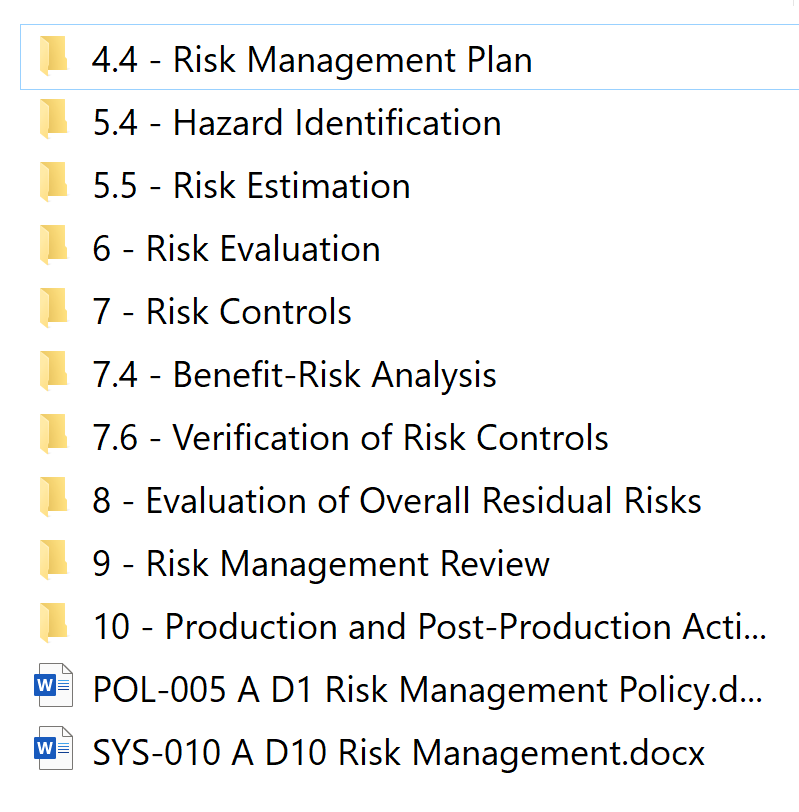

- 7.1), Planning of Product Realization & Risk Management

- 7.6), Calibration;

- 8.2.3), Monitoring & Measurement of Processes

- 8.5.2), Corrective Action; and

- 8.5.3) Preventive Action.

This strategy reduces the number of process audits needed by more than half.

Internal Auditing: Upstream/Downstream Examples

Another way to embrace the process approach to auditing is to assign auditors to upstream or downstream processes in the product realization process from their own area. For example, Manufacturing can audit Customer Service to understand better how customer requirements are confirmed during the order confirmation process. This is an example of auditing upstream because Manufacturing receives the orders from Customer Service—often indirectly through an MRP system. Using this approach allows someone from Manufacturing to identify opportunities for miscommunication between the two departments. If Regulatory Affairs audits the engineering process, this is an example of auditing downstream. Regulatory Affairs is often defining the requirements for the Technical Files and Design History Files that Engineering creates. If someone from Regulatory Affairs audits these processes, the auditor will realize what aspects of technical documentation are poorly understood by Engineering and quickly identify retraining opportunities.

Audit schedule and an audit agenda, what’s the difference? Read More »