Status of the European Medical Device Regulations?

This article describes the status of the new European Medical Device Regulations, and it provides some advice for what you should be doing to prepare for the changes.

The picture above is not a picture of people on their way to the local maple sugar shack, trying to get a car unstuck during mud season in Vermont. It’s actually a photo of paid actors reenacting the European negotiations for new medical device regulation. The European Parliament is in the overcoat on the left. The four men on the right represent the various presidents–Greek, Italian, Latvian, and Luxembourg. The Dutch President is driving the horse team in the front in the hopes of getting unstuck in time for next Spring.

Yes, in a word, the negotiations are “stuck”!

My friend Erik Vollebregt did a wonderful job of summarizing the status of negotiations on April 30, in his blog posting. The best guess anyone has is that we might have a final version released next year in Spring 2016. It’s only two years later than I was expecting. I guess they encountered more mud than expected.

There are a number of issues that the member states appear to be stuck on:

- Ingested products

- Non-medical devices

- Companion diagnostics

- Non-viable human tissues and cells

- Viable biologic substances

- Reprocessing single-use devices

- Genetic testing

- Implant cards

- Eudamed & UDI

- Summary of safety & performance

- Notified Bodies

- Pre-market approval

- Clinical investigations

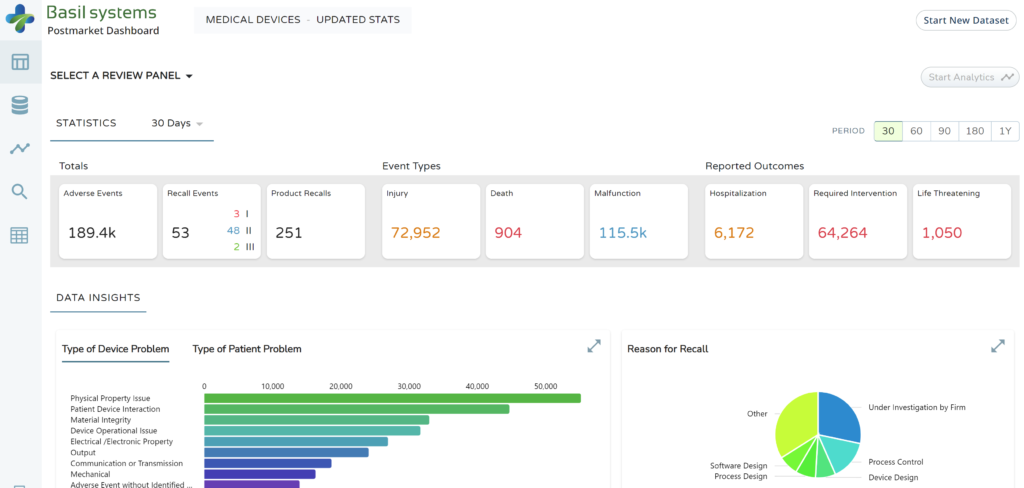

- Post-market surveillance

- Market surveillance & vigilance

- Reference laboratories

- Hazardous chemicals

- Classification rules

- Governance & oversight

I’m not quite sure whether the remaining list of issues the member states agree upon is shorter than this or longer. Still, this list includes a number of fundamental principles that could dramatically change the nature of medical device regulation in Europe. We expect that many of these issues will be resolved with a compromise of some sort. Still, I suspect every medical device manufacturer with a CE Mark will be extremely busy from 2016-2019 revising their procedures, technical documentation, and training personnel on the new European Medical Device Regulations.

What Should You Be Doing to Prepare?

- Update Your Quality System to ISO 13485:2015 Early – The second Draft International Standard (DIS2) for ISO 13485 was released in February, and the final version is expected to be published this Fall. The changes to ISO 13485 are minor, but audits by your Notified Body will be far less complicated if you upgrade your quality system to the new revision before you attempt to address the new European Medical Device Regulations.

- Strengthen Your Internal Auditing & CAPA Processes – Companies with strong internal audit programs and CAPA processes have fewer findings resulting from Notified Bodies. When you have multiple outcomes from a previous audit to close, your annual surveillance audits and recertification audits become longer and more complex. These findings must also be closed before a manufacturer may transfer a quality system or CE Certificate from one Notified Body to another. Therefore, strengthening your internal audit and CAPA processes will result in a shorter Notified Body audit, and you will find it much easier to transfer from one Notified Body to another–if your current Notified Body is no longer able to issue a CE Certificate for one or more of your products.

- Update Your Technical Files – Companies that have a Design Dossier are required to submit all changes to their Design Dossier for approval before implementation. Still, companies with a Technical File for a lower risk device have their technical documentation sampled periodically. A sampling of technical documentation allows companies to fall behind in their documentation of changes. Re-issue of new CE Certificates will require a more thorough review of these Technical Files that may not have been sampled in several years. Therefore, I recommend that companies allocate resources to updating technical documentation now so that there is less work to update the technical documentation for the new European Medical Device Regulations.

- Review Your Product Portfolio and Prune It – The more mature product lines become, the more likely it is that you have products you are maintaining that just aren’t selling. The cost of maintaining your technical documentation and updating everything for compliance with the new European Medical Device Regulations will be expensive. Therefore, you can save some money now and a larger amount of money later by eliminating any products from your CE Certificate that is not selling well. If you have customers that are still buying an older version of the product, now is the time to persuade them to transition to the current version of your product. You don’t want to maintain your Technical File for two versions of the same product.

Regardless of what compromises are made, the new European Medical Device Regulations are guaranteed to be the most substantial change in regulatory requirements that the medical device industry has endured since 2003–much more dramatic than the 2007/47/EC amendment to the Medical Device Directive (MDD).

Will someone please buy the negotiators a pair of Bogs and a Subaru Crosstrek?

Status of the European Medical Device Regulations? Read More »