This blog reviews 15 tips for creating an effective CAPA form including source, quality issue description, and the root cause investigation.

The reason for creating a “great CAPA form” is to improve the effectiveness of your CAPA process. Anyone in your company could be assigned to a CAPA, but not everyone is a CAPA expert. Therefore, designing an effective CAPA form can reduce errors and improve the effectiveness of the actions taken. You can also purchase our CAPA procedure and CAPA form, which is compliant with ISO 13485:2016.

Provide adequate space in CAPA form

The most important feature of a CAPA form is to ensure that there is adequate space for writing a complete response for each section. Having sufficient space is more important than the benefits of a shorter record.

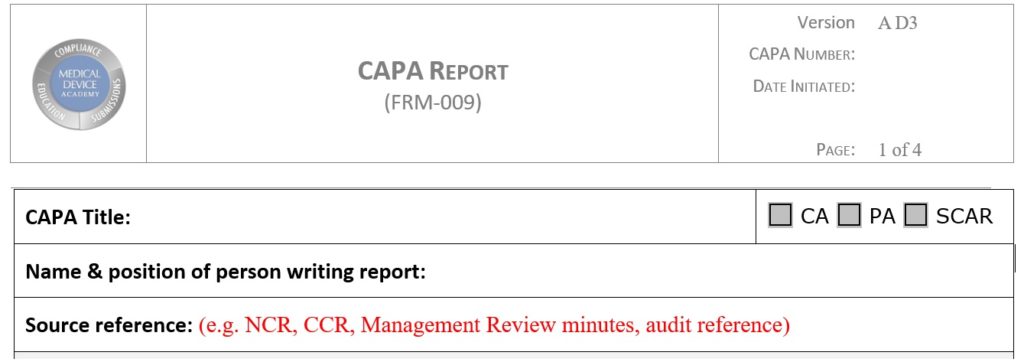

Date your CAPA form was initiated

The date your CAPA form begins to be completed can be used to verify that there was no “undue delay” in the initiation of a CAPA in response to internal audit findings. The date of initiation is also used to calculate the due date for completing the investigation and providing a corrective/preventive action plan.

Include a cross-reference number in your CAPA form

This is typically a sequentially assigned CAPA log number. Ensure the number is prominent on all pages—just in case pages are separated.

CAPA source

The source of a CAPA is useful information when performing data analysis—especially for internal audits where the audit schedule should reflect the results of previous audits. Examples of CAPA sources include:

- Complaints/Reportable Events

- Internal, Supplier, and Third-Party Audits

- Service Work Orders

- Nonconforming Materials

- Management Reviews

Description of CAPA issue

I use the word “issue” instead of nonconformity because you need a CAPA form that will work for potential nonconformities (i.e., – preventive actions), as well as nonconformities. Typically, the wording is identical to a customer complaint or an auditor’s text, but the description of the issue identifies the symptoms observed. Specific references to records, locations, times, equipment, products, and personnel involved may be necessary for the root cause investigation.

The investigator assigned and target due date for the plan

In ISO 13485:2016, the only change to the requirements for corrective actions and preventive actions was the clarification that planning is required. Since this was always implied in the standard, your procedure should already comply with clauses 8.5.2 and 8.5.3 in the 2016 version of ISO 13485.

This section of your CAPA form should identify who is going to investigate the root cause of the issue and the date that a corrective/preventive action plan is needed. The FDA requires submitting a corrective action plan for all 483 observations within 15 business days, or it will result in an automatic Warning Letter. Most certification bodies require a plan within 30 days. Your target due date should be risk-based unless there is a specific regulatory requirement. The date will also need to be based upon the date the issue was identified—not necessarily the date the CAPA was initiated.

Documenting the investigation of the root cause is the #1 item in a CAPA form

This section always reminds me of the story about the Ohno Circle. Every company asks if they can close a nonconformity during an audit, and the answer should always be “No.” You can correct a problem, but you cannot perform a root cause investigation and implement an effective corrective action during the same audit. You need to investigate the cause and the investigation documented. Some companies include a specific tool in this section, such as a “Fishbone Diagram.” This is also a mistake because there are many root cause analysis tools, and you need to select the best one for your specific situation. You might even need to use more than one tool.

Is your CAPA form missing containment of nonconforming product?

If the issue requires preventive action, there is nothing to contain. If the issue is specific to a procedure’s deficiency, there is also nothing to contain. If the issue requires corrective action and nonconforming materials or products are involved, then you need to quarantine the affected items. If the affected product has already left the company’s direct control (see 21 CFR 806.2(l) for a definition), then you have a potential recall. Regulators often look for “bracketing” or “bounding” of the upper and lower lot limits for an issue. Therefore, this section is where you document the rationale for why certain lots of products/materials are quarantined, and other lots are not.

Correction(s) – Your CAPA form must separate this from corrective actions

Fixing the immediate problem does not prevent a recurrence, but regulators will verify that each occurrence of the issue identified during the investigation of the root cause has been corrected. You should verify that each of the nonconformities identified in the original finding and the investigation is addressed in this section of your CAPA form. For preventive actions, this section is not applicable.

Corrective Action Plan/Target Due Date for Implementation

These are the steps planned to prevent a recurrence. If the plan changes, then it should be updated. There is no need to delete the old version of the plan, but the new version should include a date when the plan was revised. For preventive actions, this section is not applicable. The target date of implementation should reflect the risk associated with the issue.

Preventive action plan / target due date for implementation

These are the steps planned to prevent the occurrence of nonconformity. If an issue occurred for one product, but not for others, the actions taken for other products can be preventive. In this case, both the corrective action plan and the preventive action plan sections should be completed. The target date of implementation should reflect the risk associated with the issue.

Corrective and preventive actions implemented – Update your CAPA form weekly

This section details what specific actions were performed—both corrective and preventive actions can be documented here. The dates of completing actions should be documented, and reasons for delays and overdue actions should be identified.

How to document your plan for verification of effectiveness – CRITICAL

I recommend filling this section before the plan for corrective and preventive action is developed. This often helps the person developing the plan to ensure that the actions planned are adequate. Whenever possible, this should be quantitative, and it helps to identify a specific date for performing the effectiveness check.

Verification of effectiveness

This section of your CAPA form is where you document verification of effectiveness. Specifically, what verification activities were performed to ensure that the corrective and preventive actions you implemented were effective. The date verification of effectiveness was performed should be documented, and if the actions were not effective, then a new CAPA should be referenced here.

Signature and closure date

Someone needs to review, sign, and date your CAPA form when it is completed. Often, regulators will review only closed records.

Pingback: 8 Steps to Writing a CAPA Procedure Compliant with ISO 13485:2016 -

Thank you for your tip to make sure there is enough space for people to write their responses under each section. My brother works in the automotive industry and he was interested in CAPA software. I’ll pass this tip onto him and help him look more into CAPA.

Hi Skylar,

I’m glad you found that tip helpful. I think with CAPA software you can attach a lot of documentation with hyperlinks that often would be left out in a paper record. Therefore, you might find the space needed for certain sections of a CAPA record in a software program is just enough space for the hyperlink.

Pingback: 13 Steps to Creating a Risk-Based CAPA Process - 2021 Advanced Management Solutions

Pingback: CAPA procedure, How do you improve quality and prevent nonconformity? Medical Device Academy