The article explains requirements for a performance qualification (PQ) of EO sterilization validation and how it is different from other PQ process validations.

Performance Qualification (PQ) – What is the difference between an IQ, OQ, and PQ?

When you are performing a process validation, the acronyms IQ, OQ, and PQ sometimes confuse. IQ is the installation qualification of the equipment used in your validated process. The purpose of the installation qualification is to make sure that your equipment was installed correctly–this includes calibration and connection to utilities. OQ is the operational qualification. The purpose of the operational qualification is to make sure that the equipment you are using is capable of operating over the range of parameters that you specify to make your product. The PQ is a performance qualification. The purpose of the performance qualification is to ensure that you can consistently make a product within specifications (i.e., repeatable).

Different Definitions for Operational Qualification (OQ)

The GHTF guidance document for process validation provides the following definition for an OQ: “Establishing by objective evidence process control limits and action levels which result in a product that meets all predetermined requirements.” ISO 11135-1:2014, the international standard for ethylene oxide (EO) sterilization validation, provides a slightly different definition for an OQ: “process of obtaining and documenting evidence that installed equipment operates within predetermined limits when used in accordance with its operational procedures.” The difference in these two definitions is essential because the OQ is typically performed by contract sterilizers and does not need to be repeated unless there is a significant change or maintenance to the sterilizer that requires repeating the OQ. In contrast, when you perform an OQ for packaging, the OQ is specific to the packaging materials you are going to be sealing. Therefore a new OQ is required whenever new packaging materials are developed. For EO sterilization, the analogous step of the validation process is called a microbial performance qualification (MPQ).

Performance Qualification (PQ) = MPQ + PPQ

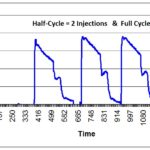

A performance qualification (PQ) for ethylene oxide sterilization validation consists of two parts: 1) microbial performance qualification (MPQ), and 2) physical performance qualification (PPQ). The microbial performance qualification is intended to determine the minimum process parameters for the EO sterilizer sufficient to ensure product bioburden is killed. These parameters are referred to as the half-cycle because the full production cycle will be twice as long in duration. For example, a half-cycle consisting of 3 injections will correspond to an entire cycle of 6 injections.

What are fractional cycles?

Fractional cycles are typically shorter in duration than the duration of a half-cycle. The purpose of a fractional cycle is to demonstrate that external biological indicators (BIs) located outside of your product, but inside the sterilization load, are more challenging to kill than internal BIs. Fractional cycles are also be used to demonstrate that the product bioburden is less resistant than the internal BIs. To achieve both of these objectives, it is typical to perform two fractional cycles at different conditions to make 100% kill of internal BIs and partial external BI kill in one fractional cycle, and 100% kill of product bioburden but only partial kill of internal BIs in the other fractional cycle. When your goal is partial kill, you should also target more than one positive BI, because this reduces the likelihood that poor technique resulted in a BI positive from growth.

Microbial Performance Qualification (MPQ)

The microbial performance qualification (MPQ) typically consists of three half-cycles and one or more fractional cycles. 100% kill of external BIs is not required for the MPQ during a half-cycle–only the internal BIs must be 100% killed, but the external BIs are only useful if 100% kill of the external BIs is achieved in the full cycles. If you are re-validating the sterilization process, you are only required to complete one-half cycle and one fractional cycle. For re-validation, the fractional cycle is intended to achieve a 100% kill of product bioburden. Still, only partial kill of internal BIs to verify that the product bioburden remains less resistant to sterilization than the internal BIs. You are also required to perform bioburden measurements of non-sterile products for the initial MPQ and re-validation to demonstrate that bioburden can be adequately recovered from the product and measured.

Physical Performance Qualification (PPQ)

The physical performance qualification (PPQ) typically consists of three full cycles and measurement of EO residuals in accordance with ISO 10993-7:2008. If PPQ is performed during the MPQ, then it is only necessary to complete one full cycle–assuming the MPQ consists of at least three half-cycles. If you are performing a re-validation of the sterilization process, then you are required to complete three full cycles and measurement of EO residuals.

Repeatability, Reproducibility, Product Variability and Environmental Factors

Typically a performance qualification (PQ) is intended to verify that the same person can repeat the process multiple times, other people can reproduce the first person’s results and any variation product from lot to lot will not prevent the process from producing an acceptable product. Besides, any variation in environmental factors should be assessed during a PQ. In sterilization processes, however, the equipment is typically automated. Therefore, variation between operators is usually a non-issue. Also, sterilization lots typically consist of a large volume of products where multiple samples are tested for sterility. Therefore, performing three runs sufficiently challenges the repeatability and reproducibility of the sterilization process–including any product variability. The issue of environmental variations in heat and humidity is addressed by designing preconditioning cycles into the sterilization process. Sensors are included in each validation load to verify that the process specifications were achieved and maintained for temperature and humidity. Still, the sensors also help to identify the worst-case locations in a load to use for sampling and placement of BIs.

If you are interested in learning more about sterilization validation, please read our blog from last year on an evaluation of the need to re-validate your sterilization process, or you can watch our webinar on sterilization and shelf-life testing. You can also purchase our procedure for EO sterilization validation by clicking on the link below.

Purchase the EO Sterilization Validation Procedure (SYS-031) – $299