This article explains the process for determining if a color change and other material changes require a new 510k before implementing the change.

I recently taught a frequently asked questions (FAQs) webinar, where I asked attendees to provide questions in advance of the webinar, and I answered the questions during the webinar. One of the attendees asked how to know if a new 510k is required if the only modification to a device is a color change.

New FDA guidance for device modifications

On August 8, 2016, the FDA released a new draft guidance document for device manufacturers regarding device modifications and when a new 510k is required. The current final guidance is titled “Deciding when to submit a 510(k) for a change to an existing device,” and that guidance is dated January 10, 1997. A draft guidance document on this topic was released several years ago, but that draft guidance was withdrawn in response to feedback from the industry. The new draft guidance document includes modified decision trees to help manufacturers decide which types of changes will require a new submission, but there are also examples provided in Appendix A. The most helpful part of the guidance, however, is Appendix B. Appendix B explains how to document changes properly—regardless of whether a change requires submission or not.

Decision Trees from the Guidance

There are five decision trees or flow charts provided in the new draft guidance. The purpose of each decision tree is identified below:

- Main flow chart

- Decision Tree A = labeling changes

- Decision Tree B = technology, engineering and performance changes

- Decision Tree C = material changes

- Decision Tree D = IVD product changes

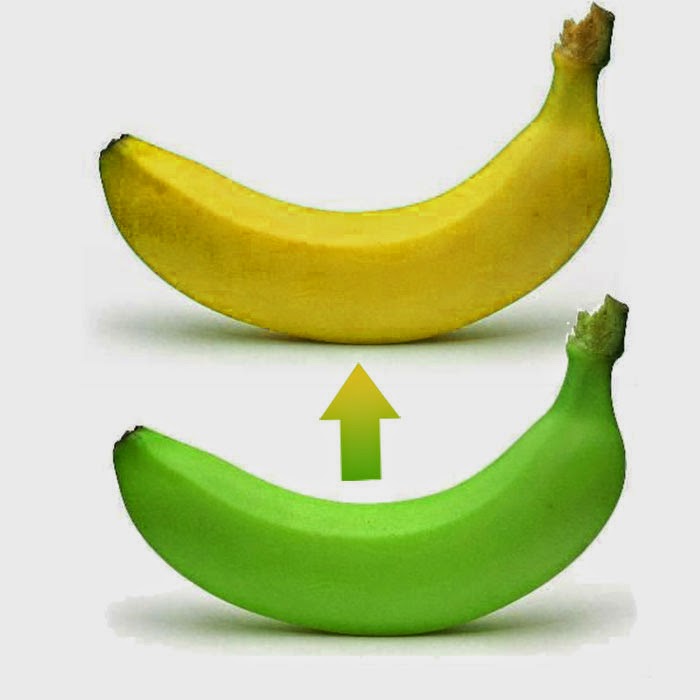

How to apply Decision Tree C to a color change

Typically adding a colorant, or changing a colorant, does not negatively impact the strength of a device, but this is the first cautionary statement made at the beginning of the section for material changes. Therefore, if your device has a performance testing requirements that involve a component that is involved in a proposed color change, then you need to repeat the performance testing to verify that the color change has not negatively impacted the strength. Sometimes large concentrations of colorant result in weakening of plastics. Therefore, repeating some of the performance testing or providing data that supports the need for no further testing is expected. In the decision tree, this is addressed by question C5, “Could the change affect performance specifications?” If no, then you document the change, but a new 510k is not required. If yes, then you refer to decision tree question B5.

The next concern addressed by Decision Tree C is the biocompatibility of your modified device. If the material change of the device or device component comes into direct contact with the body, blood, or tissues, then biocompatibility risks must be assessed. If the change does create new or increased issues related to biocompatibility, then question C4.1 asks, “Has the manufacturer used the same material in a similar legally marketed device?” If the changed material has not been used previously for a similar application, then a new 510k is required—typically a Special 510k if only the material is changed and only biocompatibility needs to be assessed by the FDA.

Reference to FDA biocompatibility guidance

Within the guidance document, the FDA explains that you may want to refer to “Use of International Standard ISO 10993-1, ‘Biological Evaluation of Medical Devices Part 1: Evaluation and Testing,’” when you are answering question C4. This new final guidance was released on June 16, 2016, and the Office of Device Evaluation (ODE) appears to be focusing much more closely on biocompatibility since this new guidance released.

Examples of material changes from FDA guidance

There are six examples of material changes presented in the new draft guidance:

- A slight change in polymer composition for a catheter = letter to file

- Change in polymer for a catheter

- Change in a polymer for a catheter to a polymer already used by another manufacturer for a 510k cleared device with the same indications = new 510k submission

- Change in a polymer for a catheter to a polymer already used by your company for another 510k cleared catheter of the same type and duration of contact = letter to file

- Change in a polymer for a catheter to a polymer already used by your company for another 510k cleared catheter of the same type but shorter duration of contact = new 510k submission

- Change in a polymer for a catheter to a polymer already used by your company for another 510k cleared catheter of the same type but longer duration of contact = letter to file

- Change in the manufacturing method of catheter tubing (i.e., molding to extrusion) = new 510k submission

- Change in material for a catheter

- The new polymer is already used by your company for another 510k cleared catheter of the same type and same duration, but the sterilization method changes (i.e., gamma to EO) = new 510k submission

- The new polymer is already used by your company for another 510k cleared catheter of the same type, duration, method of manufacturing (i.e., molding) and method of sterilization (i.e., EO) = letter to file

- The new polymer is already used by your company for another 510k cleared catheter of the same type, duration, method of manufacturing and sterilization, but the performance specifications are slightly different = letter to file (depends upon the impact of difference)

- Change in the dental implant from the untreated surface to acid-etched = new 510k submission (may also be considered a design change)

- The implantable device is marked temporarily with tape proven not to leave a residue = letter to file

Do you have other questions about biocompatibility?

On Thursday, December 1, @ 11:00 am EST, I will be hosting a new live webinar on the topic of biocompatibility. The webinar will address both requirements for 510k submissions and for CE Marking technical files. If you are interested in registering for that webinar, please click on the following link:

Do you have a question about your 510k submission?

If you have a question related to your 510k submission, you can submit your question to me and download the webinar recording for free by clicking on the following link:

I will respond to your question by email, but most questions make great future blog topics—like this one.

You might also be interested in our 510k course series:

You gain unlimited access to 24 webinars related to 510k submission.

Hi,

I seen your webinar which gave me valuable input to me. Currently one thing I wish to know your suggestion on following query.

Suppose, we need to change the device/component drawing revision with no impact on safety profile, performance and intended use then in this case letter to file is sufficient .Is that correct .So every time we need to do letter to file with change in revision of drawing even though no significant and major change as per 510k Guidance.

Awaiting your response.

The “letter to file” process does not involve submitting anything to the FDA. It is a way to document in your own design change records that a new 510(k) submission was not required. Every time you update a drawing or specification you should document the rationale why a new 510(k) is not required. However, in you own design control procedure you are allowed to define how and when you do this. If you are fixing a typo, there is no value in documenting a letter to file. However, if you change suppliers for a patient-contacting component, that could impact biocompatibility and the letter to file process should be used and documented. You need to write a procedure that gives you some “wiggle room” so that you only have to document things that matter rather than everything. You also need to take into account the classification of the device. A Class 3 device will require supplements being submitted to the FDA while a Class 2 device does not.