Do you need to purchase a protocol for packaging performance testing in accordance with ISO 11607-1 and ISO 11607-2?

Packaging Performance Testing Protocol

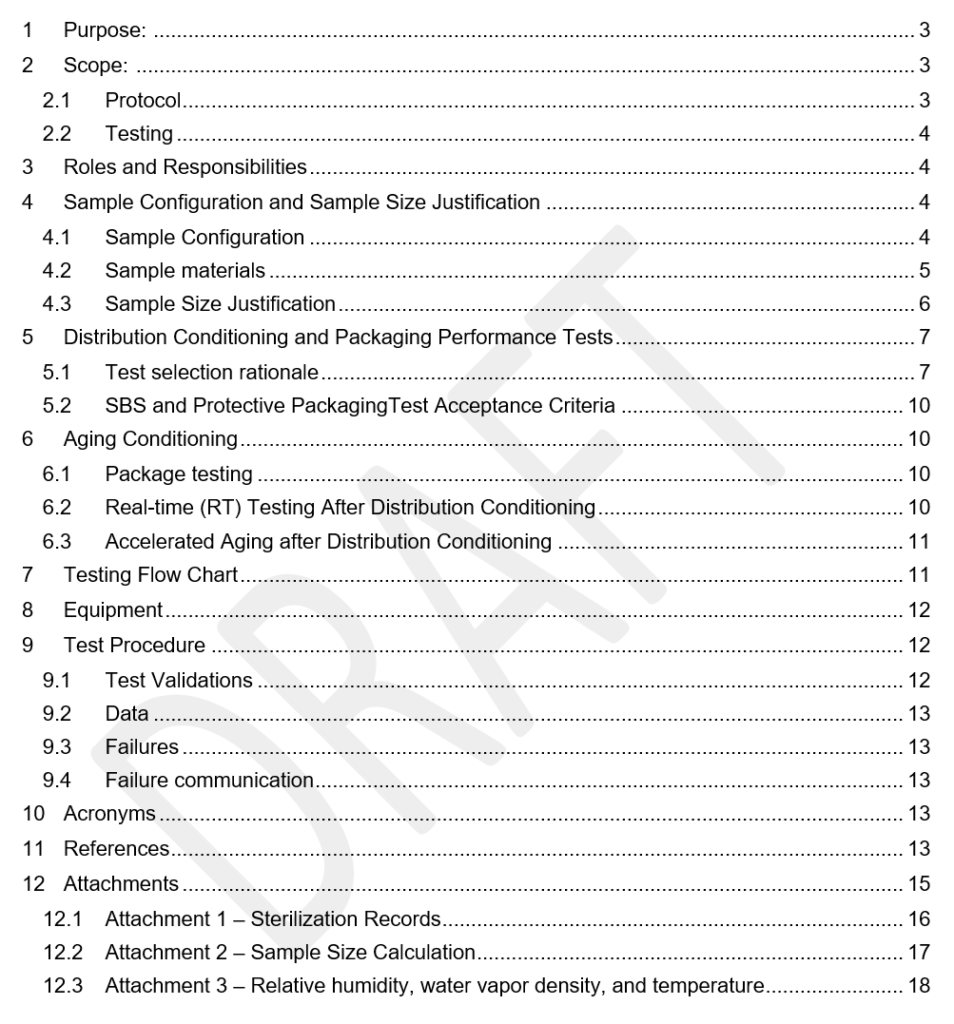

As part of your design validation, you must validate your packaging performance. If you are interested in other types of performance testing we have webinar on creating a test plan. Jan Gates was kind enough to write an 18-page Packaging Performance Testing Protocol for our customers in accordance with ISO 11607-1 and ISO 11607-2. The table of contents for this protocol is provided below.

Please note: This product will be delivered to the email address provided in the shopping cart transaction. After the transaction is verified, please check your email for the download.

Do you need more help with the validation of your packaging process?

For companies interested in packaging process validation, our procedure for process validation (SYS-014) includes an example from the GHTF for validating a packaging process. Jan Gates was kind enough to develop two other related validation protocols for our company that are available for purchase:

- Distribution Conditioning Shipping Qualification (20 pages)

- Shelf-Life Testing Protocol (13 pages)

View Our Process Validation Procedure

CLICK HERE OR IMAGE BELOW:

About Jan Gates

Jan is the owner and founder of PackWise Consulting, with 30+ years of experience in package engineering with foods, pharmaceuticals, detergents, and medical devices. Her work has included individual contributions and leading teams for packaging material and systems design/development to meet regulatory, product protection, and customer use requirements.

Jan is the owner and founder of PackWise Consulting, with 30+ years of experience in package engineering with foods, pharmaceuticals, detergents, and medical devices. Her work has included individual contributions and leading teams for packaging material and systems design/development to meet regulatory, product protection, and customer use requirements.

Her work includes packaging system validations, cold chain shipping, several types of sterilization methods, production line efficiency increases, packaging equipment, and sustainable packaging, as well as documentation procedures, policies, and project management with multiple packaging materials types and production lines.

Over the last 20 years, she has worked in the medical device industry with European (EU)/FDA/Japanese and other countries’ requirements. She was a task group leader for the AAMI TIR 22 document, a US guidance document on compliance with EN ISO 11607-1 and EN ISO 11607-2, Terminally Sterilized Medical Device Packaging. The ISO/EN 11607-1 & -2 standards were adopted as ISO/TIR 16775. She is also a member of the ASTM D10 and F2 (rigid and flexible packaging) groups that develop industry standard test methods and guidance and the IoPP Southern California chapter revitalization group.

The companies she has worked for include:

- Abbott Vascular/Guidant Corporation

- Dade Behring/Syva

- Lever Brothers

- ConAgra/Hunt Wesson Foods

- Bristol-Myers Squibb/Mead Johnson

If you need help with packaging design or developing the testing plans for packaging verification and validation, please contact her by email or phone at (650) 743-5780.